Creating commitment to quality management? This is how you make working according to processes the norm

In many organizations, the quality management system is not taken seriously enough. Executives and managers often work outside the processes established by the quality department. This can lead to many problems, including reduced efficiency and increased costs.

In this blog post we discuss how you can make working according to a process part of the daily routine on the work floor. This way you ensure that everyone is on the same page and that quality management can actually support your organization.

Why working according to a process should be the norm

There are several reasons why it is important to follow the quality management system.

- First, it increases efficiency. If everyone does things their own way, it takes longer to get things done and there is a greater chance of errors.

- Second, following the quality system makes it easier to identify and solve problems. If everyone does things their own way, it's hard to figure out where things went wrong. But if everyone follows the same process, it is much easier to identify bottlenecks and find solutions.

- Third, working according to a process ensures that everyone is on the same page. When colleagues know what to do when, there are fewer misunderstandings and mistakes.

- Fourth, working by a process makes it easier to train new employees. If everyone follows the same process, it is much easier to teach new employees what to do and how to do it.

Why co-workers sometimes don't follow company procedures

No, it's usually not unwillingness. Everyone wants the organization to be successful, and the products or services to be of the highest quality. Yet in many organizations we see that processes and procedures are not always followed.

Yet there are many reasons why colleagues choose not to follow procedures. In some cases, it may be because they don't understand the purpose of the procedure or how it fits into the bigger picture. In other cases, it may be because they have been doing their jobs a certain way for so long that they are resistant to change. Often it stems from uncertainty, because they don't know exactly where they stand.

Common causes are:

- "We've been doing this job this way for years, and it's never been a problem."

- "I don't have time to do this like the procedure says."

- "This is too complicated. I just do it my way."

- "Those manuals and processes are from the KAM department, we do the real work."

- "I didn't know there were process descriptions? Where can I find that?"

Sounds familiar? These are some of the most common objections we hear when organizations try to implement new processes or get employees to follow existing procedures.

The good news is that there are ways to overcome these objections and get everyone on board with following quality management procedures, work instructions and checklists.

How do you ensure that colleagues will follow business processes?

The best way to get colleagues to follow processes is to involve them in thinking through the process and creating the associated procedures. By involving stakeholders in the process, you can ensure that they understand and agree with the procedures.

Step 1. Identify the problem together

The first step is to sit down with the people who will be affected by the process and the associated procedures. Analyze with them what the problem is that you are trying to solve with the business process. This is an important step because it ensures that everyone is on the same page from the beginning.

Together, formulate a problem statement and objective that everyone agrees on. This statement should be clear and concise. For example, consider: "When we improve handover moment X, the entire process chain will run smoothly."

Step 2. Form a process team with the stakeholders

The next step is to form a process team with stakeholders. This team will be responsible for devising the process and associated process agreements. The team should include representatives from all departments that will be affected by the process.

The process team will continue to exist as long as the process exists. Team members may change, but the process team will remain responsible for optimizing and improving the process.

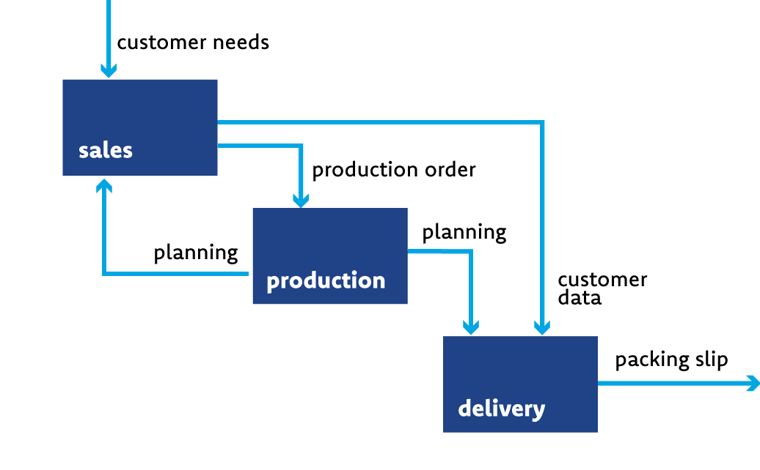

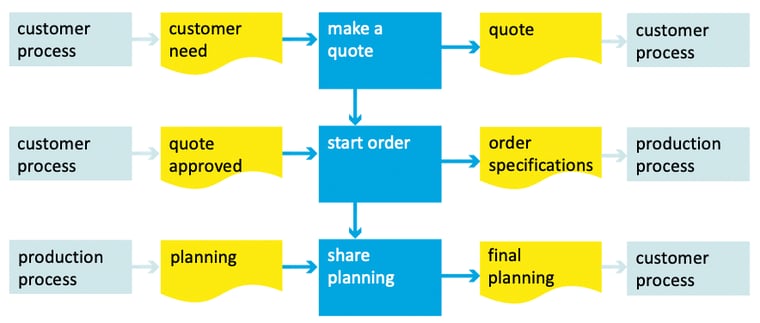

Step 3. Map the process chain using the input/output process model

It is now time to make the business process transparent. This means mapping out the process chain using the input/output process model. This will help everyone understand how the different steps in the process connect.

How to do that? In our earlier blog on digitizing business processes, we explained in detail how to map a process chain using the I/O process model.

Step 4. Make arrangements for handover moments

One of the most important aspects of any business process are the handover moments. These are the moments when the output of one (sub)process then becomes the input for the next process. In other words - these are the points at which information is transferred from one department or party to another.

It is important to agree on the minimum content and quality of information needed for a successful handover. This can be done by creating a checklist or work instruction on how the transfer should take place.

Step 5. Record these process agreements

Now that you have agreed on the minimum content and quality of information needed for each handover, it is time to put these agreements on record. You can do this, for example, in a Word document or by e-mail. However, it can be difficult for co-workers to retrieve such a document or e-mail, making it more difficult to follow the process.

It is therefore best to process these kinds of process agreements in a process management tool, such as Comm'ant. That way, everyone in the organization has easy access to it, and there is less confusion about the process agreements.

Make sure you choose a process management tool that easily integrates with your everyday tools, such as email, SharePoint, Teams, and ERP and CRM software.

In doing so, you can also use digital tools to digitize process agreements and support employees. For example, you can use Comm'ant Forms to let employees fill in information for a proper handover.

By recording the process agreements in a central location, you ensure that everyone is informed and knows where to find them.

Step 6. Let's do it!

Now that the process agreements have been established and written down in a process description, it is time to start putting them into practice. The best way to do this is to start small, with a few people who are willing to help you test the system of working agreements and tools, and then gradually roll them out to the rest of the organization.

Once you have practiced and applied the process agreements a few times, take the experiences and areas for improvement each time to the next update of these process and input/output agreements.

Step 7. Evaluate the process

After you have put the process agreements into practice, it is important to evaluate how successful they actually are.

Here you evaluate the satisfaction of the employees about the process and the satisfaction of (internal and external) customers about the quality of service.

In the start-up phase of the implementation process, evaluation is necessary on a weekly basis, so that problems can be addressed quickly. For example, make "feedback on the process" a standard agenda item of the weekly work meetings of the teams involved.

You can use various methods to collect this feedback, but always ask about what works well (compliments) and what can be improved (recommendations). Use this feedback to make necessary adjustments to process agreements and (digital) tools.

Step 8. Improve the process

Be sure to meet regularly with the process team at the drawing board. Use the compliments and recommendations to improve the process agreements.

In doing so, work bottlenecks into process improvements. For example, if filling out a certain form always takes a lot of time, see if you can automate it or make it easier for co-workers to find the information they need (for example, using Comm'ant Forms).

Step 9. Celebrate success!

Make sure you celebrate successes at least twice a year so that co-workers feel appreciated. You can do this, for example, by doing something fun or eating something tasty during the regular work meetings.

In this way you show co-workers that you are involved in the process and developments, and that you appreciate their efforts. This will motivate them to continue working according to the process agreements.

In conclusion

How do you make working by process the delusion of the day? By following the steps in this article, you can make working by process agreements the norm on the job.

Process agreements are an important part of quality management. By recording the agreements in a central location and making them accessible, everyone is aware and knows how to find them.

Employees can use digital tools to optimally implement these agreements. Evaluating and improving the process helps to keep it running smoothly. Celebrating successes shows employees that you appreciate their efforts and motivates them to keep working according to the process agreements.

If you're looking for a quality management system that can help you create and record process agreements, be sure to check out Comm'ant! Our software is designed to support quality management in organizations of all sizes.

De Nederlandse versie van dit blog tref je hier »